Case Study 6

Process Mapping for Job Clarity and Maximised Efficiency

PROBLEM: I know that I need to make more efficiencies and find smarter ways of working, but where do I start?

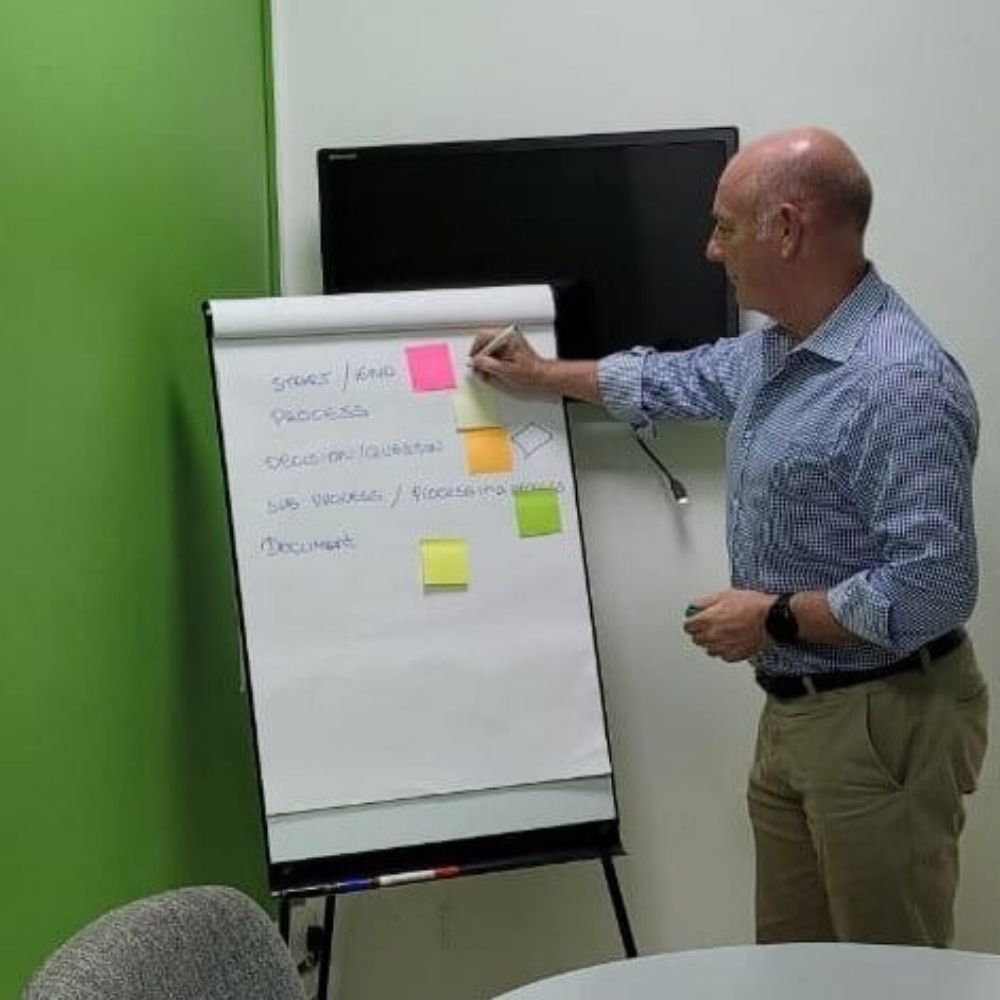

Have you ever tried to describe what you do at work? What your job is and how you perform it? We can often give a vague description, but not a detailed description. As we know, the devil (and most efficiencies) is in the detail. By process mapping, we get people to go through their work step by step. It is surprising how difficult this is, because a lot of what we do, we don’t think about! Try explaining how to park a car. It is because much of what we know is tacit knowledge, the knowledge of ‘doing’ and it is very difficult to write down. However, by mapping out a process, we capture the information in a visual format. Once we can see the steps on paper, we can start to look for efficiencies. In this case study, Helena works with a container manufacturing company to get the employees to articulate exactly what they do.

A local company was experiencing problems in various areas and could not determine where the issues arose. The CEO perceived that many of his staff were uncomfortable, although he did not know why as he frequently chatted to the ones that seemed unhappy.

There were lots of silly mistakes being made within the business, deadlines missed, and a work cycle of long days and panic working had started to take hold of the company.

During a discussion with the CEO and senior management team, it became apparent to David that the company’s organisational culture had become toxic and needed to be addressed. David explained this to the CEO and was invited to assess the staff within the central office.

From the outset, it was clear that there were several issues with the company. The senior management team believed they were approachable and friendly, but the staff did not share this view and felt that the senior management team was looking for people to sack. This feeling had developed to the point where all staff accepted that they had to focus on doing their job to the best of their ability and not get involved in other workers’ issues. This created a silo mentality that stifled communication. This lack of communication was a significant cause of the panic planning and the deadline problems.

David addressed these issues by interviewing staff and conducting participant observations. By chatting to the workers, they were provided with an opportunity to voice their concerns, making them feel better. It also enabled David to inform the worker’s that the CEO was aware of the issues and was determined to solve the problems. David also introduced culture training to highlight that a diverse workforce can have different motivations, but these motivations are deeply rooted within a workers DNA. To fight these cultural differences, by forcing workers to undertake tasks that are not culturally sensitive, such as attempting to empower those who are uncomfortable with responsibility, or not empowering or micro-managing those that are motivated by autonomy.

David also introduced a series of weekly and monthly planning and briefing events. These briefings provided the whole organisation with direction and showed the workers how their efforts interlaced with their colleagues’ efforts. This intervention broke down the silo mentality and enhanced communication. The culture training provided significant cultural awareness. This meant that all the workers, irrespective of background, found the work environment to be far more comfortable, which increased effectiveness and efficiency, ultimately helping solve the company problems

OTHER CASE STUDIES

Case 1: I have to write new procedures, but I have no idea where to start!

Case 2: I have to draft job descriptions but how can I find out what workers actually do?

Case 3: I have a diverse workforce and I don’t want to make a cultural mistake

Case 4: I have a diverse workforce and I don’t want to make a cultural mistake

Case 5: How can I motivate my workers to be more involved?